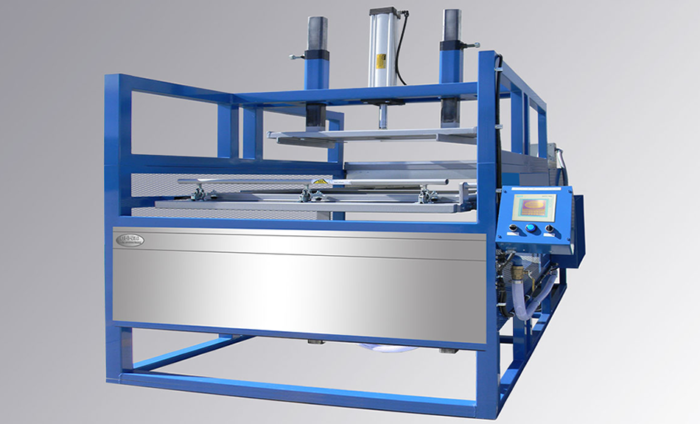

VACUUMED FORMED PARTS

Vacuum forming: commonly known by people as vacuuforming, is a simplified version of thermoforming, whereby a sheet of plastic is heated to a forming temperature, stretched onto or into a single-surface mold (BrE, mould), and held against the mold by applying vacuum between the mold surface and the sheet. The vacuum forming process can be used to make most product packaging, speaker casings and even car dashboards.

Normally, draft angles must be present in the design on the mold (a recommended minimum of 3°), otherwise release of the formed plastic and the mold is very difficult.

Vacuum forming is usually – but not always – restricted to forming plastic parts that are rather shallow in depth. A thin sheet is formed into rigid cavities for unit doses of pharmaceuticals and for loose objects that are carded or presented as point-of-purchase items. Thick sheet is formed into permanent objects such as turnpike signs and protective covers.

Relatively deep parts can be formed if the form-able sheet is mechanically or pneumatically stretched prior to bringing it in contact with the mold surface and before vacuum is applied.

Suitable materials for use in vacuum forming are conventionally thermoplastics, the most common and easiest being High Impact Polystyrene Sheeting (HIPS). This is molded around a wood, structural foam or cast/machined aluminum mold and can form to almost any shape. Vacuum forming is also appropriate for transparent materials such as acrylic which are widely used in applications for aerospace such as passenger cabin window canopies for military fixed wing aircraft and “bubbles” for rotary wing aircraft.