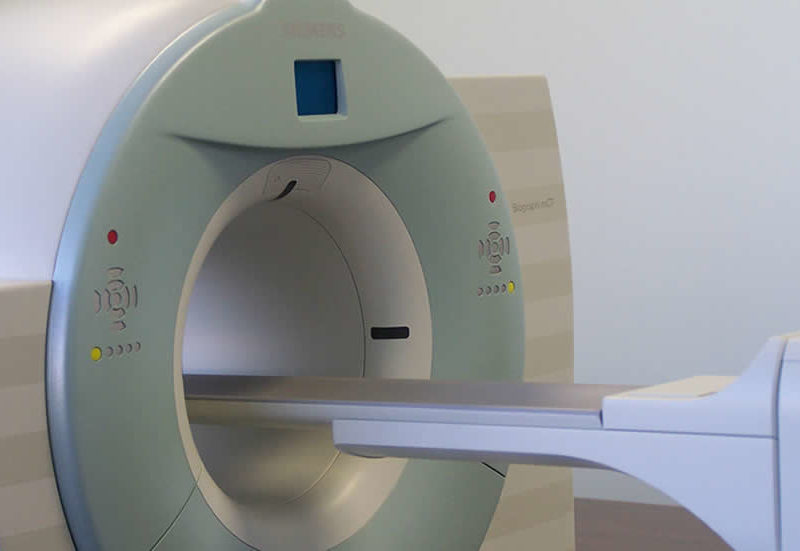

WE CREATE THE BEST PROTOTYPES

The best prototypes and models are the ones that represent what the designer and engineer want, when they want it. That is what we do.

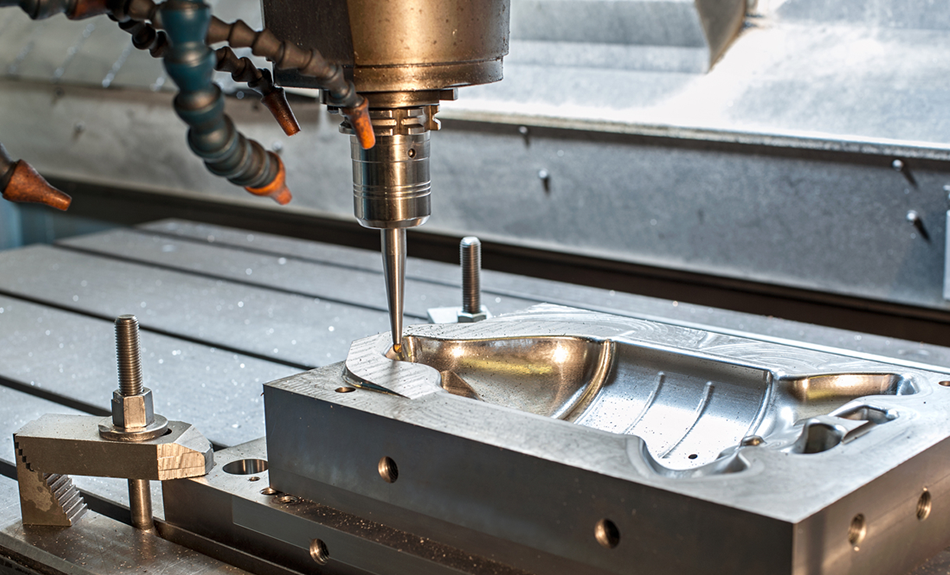

CNC machining allows Centerline to reduce your lead time to as little as one day. CNC prototypes can be cut out of almost any material, and Centerline’s post machining and finishing will provide you with the prototype or model you need to move forward with your product testing.

SLA is a rapid prototyping 3D printing method that has a long history in the model making field. It offers high accuracy and fast turn-around time.

Vacuum forming is a low cost, high-speed modeling and prototyping process. Once the mold is built, the cast is formed within minutes. Centerline can build your mold and finish your plastic part for almost any purpose. If you need one mold or 100, Centerline is your vacuum forming specialist.

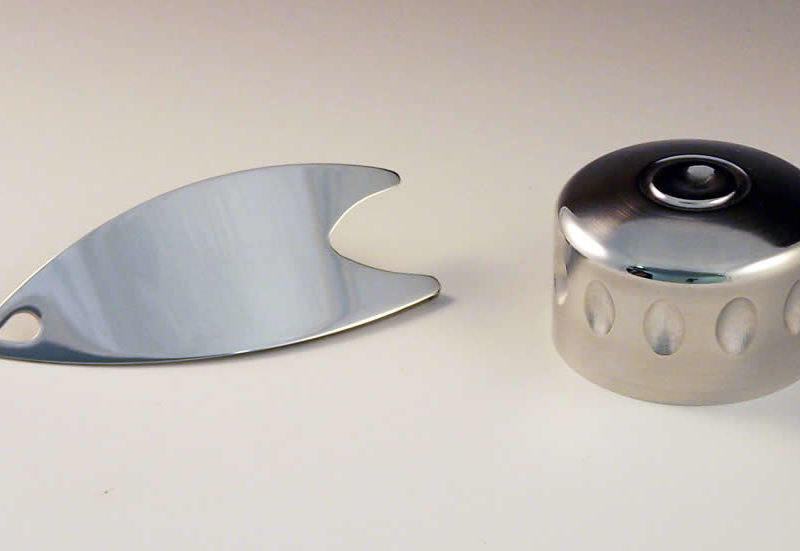

The final step in the completion of your vision. Centerline hand finishes and color matches your model or prototype to your exact specifications. With the ability to finish in many materials, texture to any specification, and paint to perfect your project; Centerline’s finishing department is second to none.